Punch Coatings

At Zimco Tool, we understand that different materials require specialized tooling solutions to maximize performance, reduce wear, and extend tool life. That’s why we offer a range of advanced punch coatings designed to optimize punching results across various materials.

Our Coating Options:

TiCN: Optimized for Stainless Steel

Titanium Carbonitride (TiCN) is the ideal coating for punching stainless steel. With its high surface hardness and low friction coefficient, TiCN significantly enhances wear resistance, reducing galling and increasing tool longevity. If you work with stainless steel, this coating ensures cleaner punches and minimizes downtime due to tool wear.

A-MAX: Superior Performance for Aluminum

Aluminum punching presents unique challenges due to its tendency to stick to tooling surfaces. Our A-MAX coating is engineered specifically for aluminum applications, offering excellent non-stick properties that minimize material buildup. This leads to more precise punches, less tool maintenance, and extended operational life.

T-MAX: Designed for Galvanized Materials

Galvanized sheets can be difficult to punch due to their zinc coating, which can lead to tool buildup and premature wear. T-MAX is formulated to combat these issues, providing superior resistance to material adhesion and ensuring consistent, high-quality punching results.

C-MAX: Optimized for Copper and Brass

Copper and brass materials can be soft and prone to deformation during punching. C-MAX is specifically developed to reduce friction and prevent excessive wear when working with these materials. With this coating, you can achieve cleaner cuts and longer tool life, reducing the need for frequent replacements.

TiN: General-Purpose Coating

Titanium Nitride (TiN) is a versatile, general-purpose coating known for its distinctive golden appearance. It enhances wear resistance and reduces friction, making it suitable for a variety of materials, including mild steels and non-ferrous metals. TiN is an excellent choice for general punching applications where a balance of performance and cost-effectiveness is desired.

Choosing the Right Coating

Selecting the right coating for your punching applications can make a significant difference in efficiency, tool longevity, and overall production costs. Whether you’re working with stainless steel, aluminum, galvanized sheets, or copper, Zimco Tool has the right coating solution to meet your needs.

For more information or to discuss the best coating option for your specific application, contact us today!

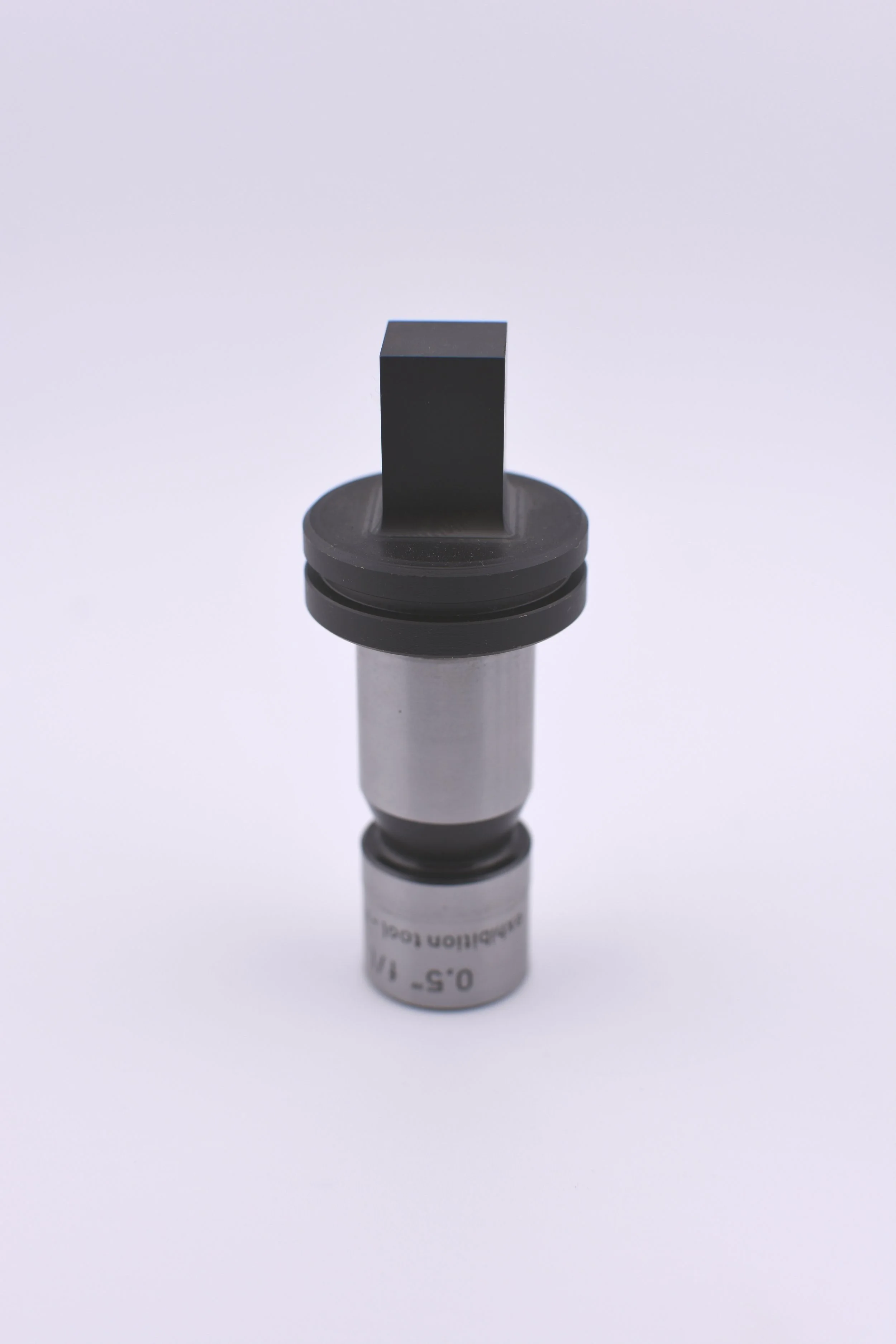

Left to right: C-MAX, A-MAX, TiN, TiCN, T-MAX